Readings Newsletter

Become a Readings Member to make your shopping experience even easier.

Sign in or sign up for free!

You’re not far away from qualifying for FREE standard shipping within Australia

You’ve qualified for FREE standard shipping within Australia

The cart is loading…

This title is printed to order. This book may have been self-published. If so, we cannot guarantee the quality of the content. In the main most books will have gone through the editing process however some may not. We therefore suggest that you be aware of this before ordering this book. If in doubt check either the author or publisher’s details as we are unable to accept any returns unless they are faulty. Please contact us if you have any questions.

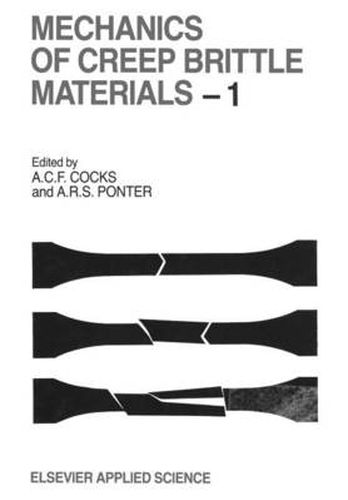

Failure of components which operate in the creep range can result either from the growth of a dominant crack or through the accumulation of ‘damage’ in the material. Conventional and nuclear power generating plant are generally designed on the basis of continuum failure, with assessment routes providing an indication of the effects of flaws on component performance. Another example where an understanding of creep failure is important is in the design of offshore structures which operate in arctic waters. These structures can be subjected to quite considerable forces by wind-driven ice sheets, which are limited by failure of the ice sheet. Design codes are currently being developed which identify the different mechanisms of failure, ranging from continuum crushing to radial cracking and buckling of the ice sheet. Our final example concerns engineering ceramics, which are currently being considered for use in a wide range of high-temperature applications. A major problem preventing an early adoption of these materials is their brittle response at high stresses, although they can behave in a ductile manner at lower stresses. In each of the above situations an understanding of the processes of fast fracture, creep crack growth and continuum failure is required, and in particular an understanding of the material and structural features that influence the transition from brittle to ductile behaviour. The translation of this information to component design is most advanced for metallic components.

$9.00 standard shipping within Australia

FREE standard shipping within Australia for orders over $100.00

Express & International shipping calculated at checkout

Stock availability can be subject to change without notice. We recommend calling the shop or contacting our online team to check availability of low stock items. Please see our Shopping Online page for more details.

This title is printed to order. This book may have been self-published. If so, we cannot guarantee the quality of the content. In the main most books will have gone through the editing process however some may not. We therefore suggest that you be aware of this before ordering this book. If in doubt check either the author or publisher’s details as we are unable to accept any returns unless they are faulty. Please contact us if you have any questions.

Failure of components which operate in the creep range can result either from the growth of a dominant crack or through the accumulation of ‘damage’ in the material. Conventional and nuclear power generating plant are generally designed on the basis of continuum failure, with assessment routes providing an indication of the effects of flaws on component performance. Another example where an understanding of creep failure is important is in the design of offshore structures which operate in arctic waters. These structures can be subjected to quite considerable forces by wind-driven ice sheets, which are limited by failure of the ice sheet. Design codes are currently being developed which identify the different mechanisms of failure, ranging from continuum crushing to radial cracking and buckling of the ice sheet. Our final example concerns engineering ceramics, which are currently being considered for use in a wide range of high-temperature applications. A major problem preventing an early adoption of these materials is their brittle response at high stresses, although they can behave in a ductile manner at lower stresses. In each of the above situations an understanding of the processes of fast fracture, creep crack growth and continuum failure is required, and in particular an understanding of the material and structural features that influence the transition from brittle to ductile behaviour. The translation of this information to component design is most advanced for metallic components.