Readings Newsletter

Become a Readings Member to make your shopping experience even easier.

Sign in or sign up for free!

You’re not far away from qualifying for FREE standard shipping within Australia

You’ve qualified for FREE standard shipping within Australia

The cart is loading…

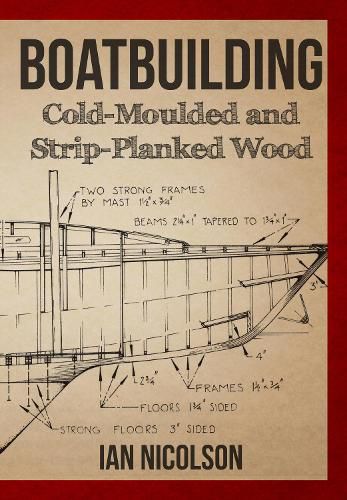

Cold-moulded wood boatbuilding predates fibreglass and has been used successfully for sailing dinghies, offshore racing yachts, fast multihulls and powerboats, and even rowing shells. It involves bonding together layers of wood veneers or thin planks to make a strong, lightweight and watertight hull. Modern glues, particularly epoxy resins, gave cold-moulding a boost and improved both its strength for weight and longevity. Strip-planking is a related technique using narrow strips of wood, and it too has been improved by modern adhesives. The two forms of building can also be combined. Both of these techniques have been used in some excellent boats, by both professionals and amateurs. They are particularly suited to one-off or short series production, and allow the moulds to be dismantled and even modified for later use. Cost and time factors are attractive, and for amateurs without a high degree of woodworking skill good results are quite feasible. This book is a practical guide to both methods, starting from the design requirements, necessary tools and working conditions, and choice of timber through step-by-step construction and repair. Ian Nicolson’s many drawings illustrate the process and provide examples of a variety of successfully built boats.

$9.00 standard shipping within Australia

FREE standard shipping within Australia for orders over $100.00

Express & International shipping calculated at checkout

Cold-moulded wood boatbuilding predates fibreglass and has been used successfully for sailing dinghies, offshore racing yachts, fast multihulls and powerboats, and even rowing shells. It involves bonding together layers of wood veneers or thin planks to make a strong, lightweight and watertight hull. Modern glues, particularly epoxy resins, gave cold-moulding a boost and improved both its strength for weight and longevity. Strip-planking is a related technique using narrow strips of wood, and it too has been improved by modern adhesives. The two forms of building can also be combined. Both of these techniques have been used in some excellent boats, by both professionals and amateurs. They are particularly suited to one-off or short series production, and allow the moulds to be dismantled and even modified for later use. Cost and time factors are attractive, and for amateurs without a high degree of woodworking skill good results are quite feasible. This book is a practical guide to both methods, starting from the design requirements, necessary tools and working conditions, and choice of timber through step-by-step construction and repair. Ian Nicolson’s many drawings illustrate the process and provide examples of a variety of successfully built boats.