Readings Newsletter

Become a Readings Member to make your shopping experience even easier.

Sign in or sign up for free!

You’re not far away from qualifying for FREE standard shipping within Australia

You’ve qualified for FREE standard shipping within Australia

The cart is loading…

This title is printed to order. This book may have been self-published. If so, we cannot guarantee the quality of the content. In the main most books will have gone through the editing process however some may not. We therefore suggest that you be aware of this before ordering this book. If in doubt check either the author or publisher’s details as we are unable to accept any returns unless they are faulty. Please contact us if you have any questions.

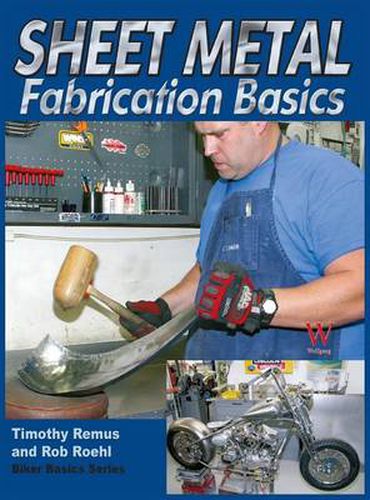

Sheet Metal Fabrication Basics gives the reader the knowledge needed to shape sheet metal without the need for expensive power tools. The reader needs only a simple shop equipped with the most basic of tools. Master craftsmen like Rob Roehl from the shop of Donnie Smith, discuss the types of steel and aluminum that are best suited to motorcycle projects, how to plan and layout a project, and how to stretch and shrink sheet metal without a power hammer and without a Pullmax.

The key is planning, then shaping primarily by stretching. Eventually the various panels must be joined through careful welding. And though many professionals use TIG equipment, there’s no reason you can’t weld both steel and aluminum with gas welding, as demonstrated in the book.

Start to finish projects include the creation of an air cleaner cover, a seat pan, and a complete fender. The book covers a wide range of techniques, from hand stretching with a hammer and a bag of shot, to shrinking with a small hand operated shriker/stretcher, use of a hammer and dolly, and the use of an English wheel, both to shape metal and to smooth out the lumps and bumps left by typical hammer work.

$9.00 standard shipping within Australia

FREE standard shipping within Australia for orders over $100.00

Express & International shipping calculated at checkout

This title is printed to order. This book may have been self-published. If so, we cannot guarantee the quality of the content. In the main most books will have gone through the editing process however some may not. We therefore suggest that you be aware of this before ordering this book. If in doubt check either the author or publisher’s details as we are unable to accept any returns unless they are faulty. Please contact us if you have any questions.

Sheet Metal Fabrication Basics gives the reader the knowledge needed to shape sheet metal without the need for expensive power tools. The reader needs only a simple shop equipped with the most basic of tools. Master craftsmen like Rob Roehl from the shop of Donnie Smith, discuss the types of steel and aluminum that are best suited to motorcycle projects, how to plan and layout a project, and how to stretch and shrink sheet metal without a power hammer and without a Pullmax.

The key is planning, then shaping primarily by stretching. Eventually the various panels must be joined through careful welding. And though many professionals use TIG equipment, there’s no reason you can’t weld both steel and aluminum with gas welding, as demonstrated in the book.

Start to finish projects include the creation of an air cleaner cover, a seat pan, and a complete fender. The book covers a wide range of techniques, from hand stretching with a hammer and a bag of shot, to shrinking with a small hand operated shriker/stretcher, use of a hammer and dolly, and the use of an English wheel, both to shape metal and to smooth out the lumps and bumps left by typical hammer work.